China Finally Has a Rival as the World’s Factory Floor

Companies look to find a backup for manufacturing and India is making its case

Western companies are desperately looking for a backup to China as the world’s factory floor, a strategy widely termed “China plus one.”

India is making a concerted push to be the plus one.

Only India has a labor force and an internal market comparable in size to China’s; India’s population may be the world’s largest, according to the United Nations. Western governments see democratic India as a natural partner, and the Indian government has pushed to make the business environment more friendly than in the past.

It scored a coup with the decision by Apple to significantly expand iPhone production in India, including expediting the manufacturing of its most advanced model.

Signs that India is changing are visible at the sprawling industrial parks in Sriperumbudur, a city in the southern state of Tamil Nadu. Foreign manufacturers here have long churned out cars and appliances for the Indian market. They’re now being joined by multinational corporations making goods from solar panels and wind turbines to toys and footwear, all looking for an alternative to China.

In 2021 Denmark’s Vestas, one of the world’s largest wind-turbine manufacturers, built two new factories in Sriperumbudur. Its six assembly lines now assemble hub cells, power trains and other components, stacked high in a storage yard to be shipped across the world.

Forecasts that India would soon become the second-largest market for turbines sparked Vestas’s expansion. But it was also a conscious effort to diversify away from China, which hosted the bulk of its regional production, especially after repeated lockdowns under Beijing’s zero-Covid policy, said Charles McCall, who oversaw the expansion as senior director of Vestas Assembly India. “We don’t want all our eggs in one basket in China.”

Some of Vestas’s suppliers have joined it. American contract manufacturer TPI Composites moulds 260-foot-long turbine blades that regularly draw attention as they are shuttled along surrounding highways. It has expanded significantly in India even as it reduces operations in China. Eventually, 85% of Vestas’s suppliers will be in India, said Mr. McCall, who recently left the company.

China still towers over every other country in global manufacturing, a position it cemented when multinationals flooded in after it joined the World Trade Organization in 2001. But a growing list of factors has prompted companies to search for a backup. First, there were rising labor costs in China and pressure from the Chinese government to transfer technology to Chinese competitors. Then there were President Donald Trump’s tariffs on Chinese imports in 2018, Covid lockdowns from 2020 through last year, and now a push by Western governments to decouple their economies from China.

Many countries are competing to be the “plus one,” with Vietnam, Mexico, Thailand and Malaysia in particular contention.

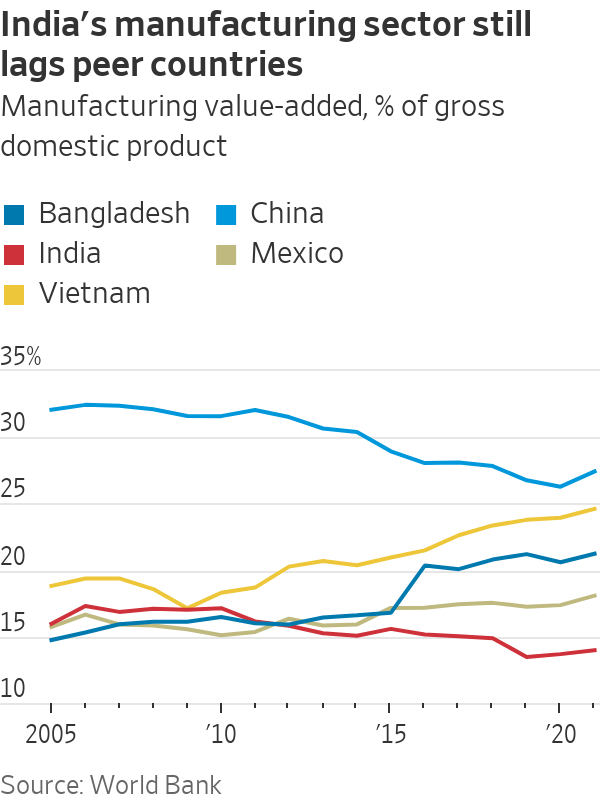

India must still overcome entrenched problems that have kept it a bit player in global supply chains. Its labor force remains mostly poor and unskilled, infrastructure is underdeveloped and the business climate, including regulations, can be burdensome. Manufacturing remains small relative to the size of India’s economy.

Nonetheless, after decades of disappointment, it is making progress. Its manufactured exports were barely a tenth of China’s in 2021, but they exceeded all other emerging markets except Mexico’s and Vietnam’s, according to World Bank data.

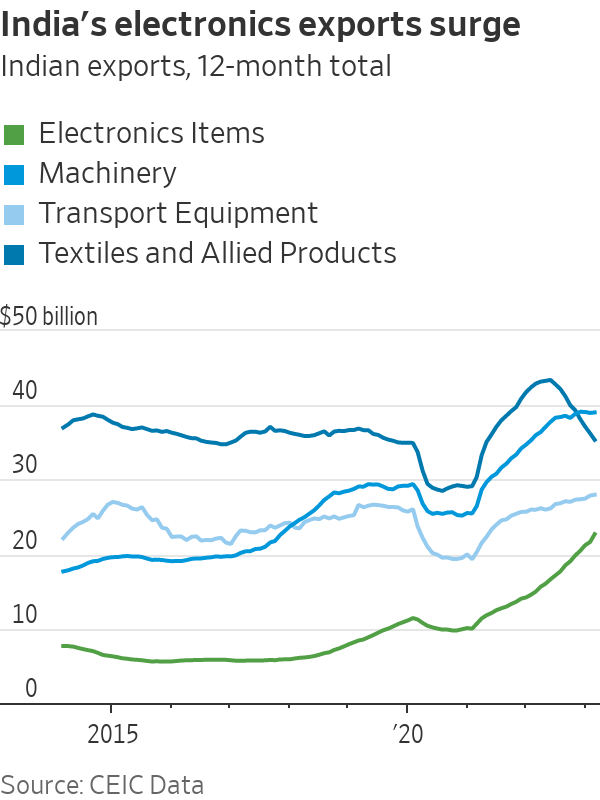

The biggest gains have been in electronics, where exports have tripled since 2018 to $23 billion in the year through March. India has gone from making 9% of the world’s smartphone handsets in 2016 to a projected 19% this year, according to Counterpoint Technology Market Research.

Foreign direct investment into India averaged $42 billion annually from 2020 to 2022, a doubling in under a decade, according to central-bank figures.

Since China declared a “no limits” friendship with Russia on the eve of the invasion of Ukraine last year, the U.S. and its allies have stepped up efforts to reduce dependence on China. Through “friendshoring,” the U.S. is “strengthening integration with our many trusted trading partners–including India,” Treasury Secretary Janet Yellen said on a visit there in February.

No company better embodies the bet on India as the next China than Apple. Over the past 15 years, the company built up a state-of-the-art supply chain almost entirely in China to make its laptops, iPhones and accessories. Its presence helped the entire manufacturing sector in China.

The California-based company has assembled lower-end iPhone models in India since 2017 and began making its newest, flagship iPhone 14 here within weeks of its launch last year. J.P. Morgan estimates a quarter of all Apple iPhones will be made in India by 2025.

Indian officials hope Apple’s presence will spur others to come. “Very often you have anchor companies who set the trend,” commerce and industry minister Piyush Goyal said in an interview. “We believe that this will send a strong signal…to other companies in Europe, America and Japan.”

Apple has been pushing suppliers to diversify beyond China after many faced production disruptions during Covid lockdowns. Meanwhile, geopolitical tensions have been growing between the U.S. and China, as well as between Beijing and Taiwan, where Foxconn Technology Group, Apple’s main manufacturer, is based.

Foxconn is set to expand production of iPhones at its existing plant near the Indian city of Chennai. It aims to boost iPhone production to around 20 million units annually by 2024 and roughly triple the number of workers to as many as 100,000, according to people familiar with the matter, The Wall Street Journal has reported.

An Apple spokesman declined to comment.

India has made progress overcoming some barriers to business. In 2014 Indian Prime Minister Narendra Modi unveiled “Make in India,” an effort to boost manufacturing. India has digitised many government services and accelerated construction of railroads, airports, container shipping ports, and electricity generation.

Mr. Goyal pointed to India’s rise on the World Bank’s ease of doing business rankings and the World Intellectual Property Organization’s global innovation index and a growing number of free trade pacts as evidence “we have now taken…integrating ourselves with other countries far more seriously.”

India introduced tax and customs rebates for exports in 2015 and overhauled them in 2021. The customs rebates were “the trigger point for the entire electronic industry,” said Sasikumar Gendham, managing director of Finland’s Salcomp, the world’s largest maker of smartphone chargers and supplier to Apple.

Since 2014, Salcomp’s Indian workforce has increased sixfold to 12,000 and it aims to hire 25,000 people in the next two years.

With 200 buses to transport workers and plans to build dormitories for 15,000 people, the company’s campus is massive by Indian standards, though not yet by Chinese standards. The facility churns out about 100 million units every year, compared with its China facility which produces about 180 million units.

For all this progress, it isn’t clear it’s enough to set India apart. Jules Shih, a Chennai-based director of Taiwan’s trade promotion agency, TAITRA, said India has become an easier place to do business, but in many respects still lags behind other countries.

It can take longer to get land and approvals to set up a factory in India and getting visas for expatriate technicians, managers and engineers is time consuming, Mr. Shih said. “We feel they don’t have a united goal integrated across agencies to make Make in India happen faster,” he said.

In March 2020, India introduced “production-linked incentives” that directly subsidise targeted products, starting with mobile phones and components, pharmaceuticals and medical devices.

Some companies have found the process to claim the production-linked incentives to be burdensome. South Korean technology giant Samsung Electronics has been in discussions with authorities over the amount of the rebate. A Samsung India spokesman said the company is committed to being a partner of India and working to make the plan a success.

Labor shortages are emerging in India’s manufacturing hubs, local officials and businesses say. That’s because, unlike in China, many workers are reluctant to relocate long distances in search of work. Trade unions are stronger in India than China.

China encouraged foreign companies to locate supply chains in special economic zones with reduced tariffs on imported components and machinery. By contrast, “Make in India” sought to replace imports with domestically manufactured products by raising import tariffs.

Those tariffs discourage industries that import many components. “India is protectionist in precisely those sectors, goods manufacturing, where the China+1 opportunity arises,” Viral Acharya, an economist at New York University and former deputy governor of India’s central bank, wrote in a report for the Brookings Institution released in March.

In its annual review of India’s economy last December, the International Monetary Fund said its integration into global value chains has stalled.

Manufacturing’s share of Indian economic output has actually shrunk since Make in India was launched, to 14% in 2021-–far below that of Mexico, Vietnam and Bangladesh.

Arvind Subramanian, who was Mr. Modi’s chief economic adviser from 2014 to 2018, said for every company such as Apple that has embraced India, several report bad experiences. Even Apple’s investment “wouldn’t have happened without the push from China,” he said.

Amazon.com closed some of its Indian ventures last fall. “We continue to develop and grow the local e-commerce ecosystem,” Amazon said in a statement.

China’s experience suggests creating lots of moderately paid jobs for less-educated rural workers, especially women, requires manufacturing.

In Tamil Nadu, a homegrown unicorn, Ola Electric, embodies those hopes. India is the world’s largest market for two-wheeled motorcycles and scooters, and Ola has made a splash with its brightly painted scooters catering to demand for electric vehicles.

New registrations for electric two-wheelers have grown more than tenfold over the past two years to 684,273 in the latest financial year ended March 31, according to the Council on Energy, Environment and Water, a New Delhi-based think tank.

Ola is making half a million electric scooters a year from its new plant. It plans to quadruple factory floor space, including two acres reserved for an indoor forest. The company says it will start making electric cars from early 2024.

The airy plant has an almost all-female workforce, from security guards to workers wielding spray guns of paint, to those who test-ride the final product.

“Initially, their parents were hesitant to let them work in factories,” said Jayaraman G., Ola’s associate director of corporate affairs. “No more. In the last one year, they saw how the situation changed financially–from paying for the education of their siblings to helping build two- or three-room apartments. It’s a proud moment for their families.”

Copyright 2020, Dow Jones & Company, Inc. All Rights Reserved Worldwide. LEARN MORE

Copyright 2020, Dow Jones & Company, Inc. All Rights Reserved Worldwide. LEARN MORE

This stylish family home combines a classic palette and finishes with a flexible floorplan

Just 55 minutes from Sydney, make this your creative getaway located in the majestic Hawkesbury region.

Continued stagflation and cost of living pressures are causing couples to think twice about starting a family, new data has revealed, with long term impacts expected

Australia is in the midst of a ‘baby recession’ with preliminary estimates showing the number of births in 2023 fell by more than four percent to the lowest level since 2006, according to KPMG. The consultancy firm says this reflects the impact of cost-of-living pressures on the feasibility of younger Australians starting a family.

KPMG estimates that 289,100 babies were born in 2023. This compares to 300,684 babies in 2022 and 309,996 in 2021, according to the Australian Bureau of Statistics (ABS). KPMG urban economist Terry Rawnsley said weak economic growth often leads to a reduced number of births. In 2023, ABS data shows gross domestic product (GDP) fell to 1.5 percent. Despite the population growing by 2.5 percent in 2023, GDP on a per capita basis went into negative territory, down one percent over the 12 months.

“Birth rates provide insight into long-term population growth as well as the current confidence of Australian families,” said Mr Rawnsley. “We haven’t seen such a sharp drop in births in Australia since the period of economic stagflation in the 1970s, which coincided with the initial widespread adoption of the contraceptive pill.”

Mr Rawnsley said many Australian couples delayed starting a family while the pandemic played out in 2020. The number of births fell from 305,832 in 2019 to 294,369 in 2020. Then in 2021, strong employment and vast amounts of stimulus money, along with high household savings due to lockdowns, gave couples better financial means to have a baby. This led to a rebound in births.

However, the re-opening of the global economy in 2022 led to soaring inflation. By the start of 2023, the Australian consumer price index (CPI) had risen to its highest level since 1990 at 7.8 percent per annum. By that stage, the Reserve Bank had already commenced an aggressive rate-hiking strategy to fight inflation and had raised the cash rate every month between May and December 2022.

Five more rate hikes during 2023 put further pressure on couples with mortgages and put the brakes on family formation. “This combination of the pandemic and rapid economic changes explains the spike and subsequent sharp decline in birth rates we have observed over the past four years,” Mr Rawnsley said.

The impact of high costs of living on couples’ decision to have a baby is highlighted in births data for the capital cities. KPMG estimates there were 60,860 births in Sydney in 2023, down 8.6 percent from 2019. There were 56,270 births in Melbourne, down 7.3 percent. In Perth, there were 25,020 births, down 6 percent, while in Brisbane there were 30,250 births, down 4.3 percent. Canberra was the only capital city where there was no fall in the number of births in 2023 compared to 2019.

“CPI growth in Canberra has been slightly subdued compared to that in other major cities, and the economic outlook has remained strong,” Mr Rawnsley said. “This means families have not been hurting as much as those in other capital cities, and in turn, we’ve seen a stabilisation of births in the ACT.”

This stylish family home combines a classic palette and finishes with a flexible floorplan

Just 55 minutes from Sydney, make this your creative getaway located in the majestic Hawkesbury region.